The company is actively engaged in Cathodic Protection related comprehensive design and project management services for projects that are typically, cross country pipelines, Complex Plant Underground piping, Onshore and Offshore facilities, City Gas and Water mains, above ground storage tanks, concrete steel structures etc.

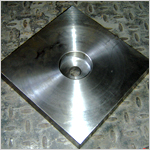

PRODUCTS & SERVICES | Pure Iron Anodes

Pure iron anode is mostly used for the protection of copper alloys of heat exchanger, fresh water facility, desalination plant (evaporator, brine heater) and condenser. It is also used as a positive pole that has much less carbon than other general irons. This cast iron anode is especially useful in stress corrosion of copper alloys. Corrosion Matters pure iron anode is developed based on over 10 years' production experience and sacrificial anode technology (used for marine and platform). For marine equipments, pure iron CP system is the most cost-effective solution to control corrosion. For packing, our company adopts wooden boxes, which are suitable for ocean transportation. This packing method can even avoid deformation.

Chemical Compositions of Pure Iron Anode

| Carbon | 0.004% max |

| Silicon | 0.01% max |

| Manganese | 0.2% max |

| Phosphorus | 0.01% max |

| Sulphur | 0.007% max |

| Aluminium | 0.15-0.5% |

| Chromium | 0.1% max |

| Nickel | 0.01% max |

| Copper | 0.2% max |

| Iron | Remainder |

Electrochemical Properties of Cast Iron Anode

| Capacity | 860 A.Hr/KG |

| Current Density | 200 mA/m2 |

Corrosion Matters is a professional manufacturer and supplier of pure iron anode in India. In addition to this cast iron anode, we are also engaged in producing magnesium anode, aluminum anode, zinc anode, etc. Based on 12 years' production experience, our products have been exported to the United States, Canada, Britain, Germany, Iran, Pakistan, India, Kuwait, Dubai, Saudi Arabia, the Philippines, Malaysia, Singapore, Congo, Turkey, etc.