The company is actively engaged in Cathodic Protection related comprehensive design and project management services for projects that are typically, cross country pipelines, Complex Plant Underground piping, Onshore and Offshore facilities, City Gas and Water mains, above ground storage tanks, concrete steel structures etc.

PRODUCTS & SERVICES | iron anodes

The Corrosion matters Shall Be Responsible for the Design, Manufacturing, Assembly and Performance Conforming to conditions and Requirements in the Specification.

The corrosion Matters Shall Verify the performance of cathodic Protection system using sacrificial anodes.

REFERENCE DOCUMENTS CODE AND STANDARDS

Material equipments supplied shall comply with the latest edition of the reference listed below. Unless Other Wise Noted.

| 004 E3264a-0501: | General Requirements for Equipment and System. |

| 004BC000-0505 : | General Design Basis and Environmental Condition. |

| 004E3204a-4510 : | Specification for Sea water Destination unit. |

| KE-003964 : | Specification for MSF Evaporator |

Saudi Aramco Specification:

| AMSS-006 : | Galvanic Anodes for Cathodic Protection(Sections 6 and 9.3 only) |

Design Service Conditions for Anode:

| Current Density : | 300mA/m2 For Sea Water, Fe Anode 150mA/m2For Brine <70oC, 100% Fe Anode 75mA/m2 For Brine>70oC, 9%Ni-91% Fe Anode |

| Anode Consumption Rate : | 9.2 Kg/Amp-Yr-100%Fe Anode 10.2Kg/Amp-Yr, 9%Ni-91%Fe Anode |

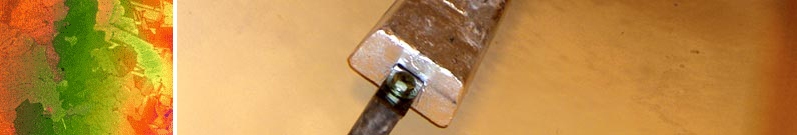

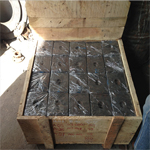

TYPES OF IRON ANODES PURE AND ALLOY TYPE

Two Types Of sacrificial Anodes shall be used for the corrosion Protection

100% Iron anode For Sea water and decorated Brine Service at temperature below 700C

*Composition % by Weight:

| Carbon (C): | 0.12% max |

| Manganese (P): | 0.9% max |

| Phosphorous (P): | 0.03% max |

| Sulfur (S): | 0.03% max |

| Silica (Si): | 0.15-03% |

| Ferrous (Fe): | Remainder |